The Problem

Factories and critical infrastructure lose staggering amounts of money every year because equipment fails unexpectedly. Global estimates suggest unplanned downtime costs industrial manufacturers between 5% and 20% of productive capacity, translating into hundreds of billions of dollars annually once lost production, rush repairs, and safety incidents are counted. Traditional maintenance strategies fall into two buckets: run-to-failure (fix it when it breaks) and preventive maintenance (fixed-interval service based on time or usage). Both approaches either accept frequent disruptions or waste money servicing equipment that could have safely run longer.

The societal impact goes well beyond lost profits. Unplanned outages in sectors like power generation, oil and gas, transportation, and water treatment can disrupt essential services for thousands or millions of people. A survey of Industry 4.0 case studies reports that maintenance costs often consume 15–40% of total operating expenses in asset-heavy industries, with a large share tied to emergency repairs and downtime. Safety is also at stake: mechanical failures are implicated in a substantial fraction of industrial accidents and near misses, especially where rotating machinery and high pressures are involved.

Traditional approaches fall short because they do not use the rich sensor data now streaming off machines. Time-based maintenance assumes average behavior and ignores how actual vibration, temperature, or load patterns differ from unit to unit. Condition-based maintenance helps, but it usually relies on manual interpretation of signals by experts, which does not scale across thousands of assets and can still miss subtle early-warning patterns.

What Research Shows

In controlled, retrospective studies using historical sensor data, machine learning models routinely beat traditional rule-based approaches for predicting failures. A 2024 study on industrial equipment (centrifuges, pumps, compressors) reported that deep neural networks achieved area under the ROC curve (AUROC) values above 0.95 for failure prediction, outperforming random forests and gradient boosting models and far exceeding threshold-based baselines. Earlier work on multi-stage predictive maintenance frameworks reported diagnostic accuracies around 97% and prognostic accuracies near 90% on benchmark datasets, compared with substantially lower performance for classic statistical methods.

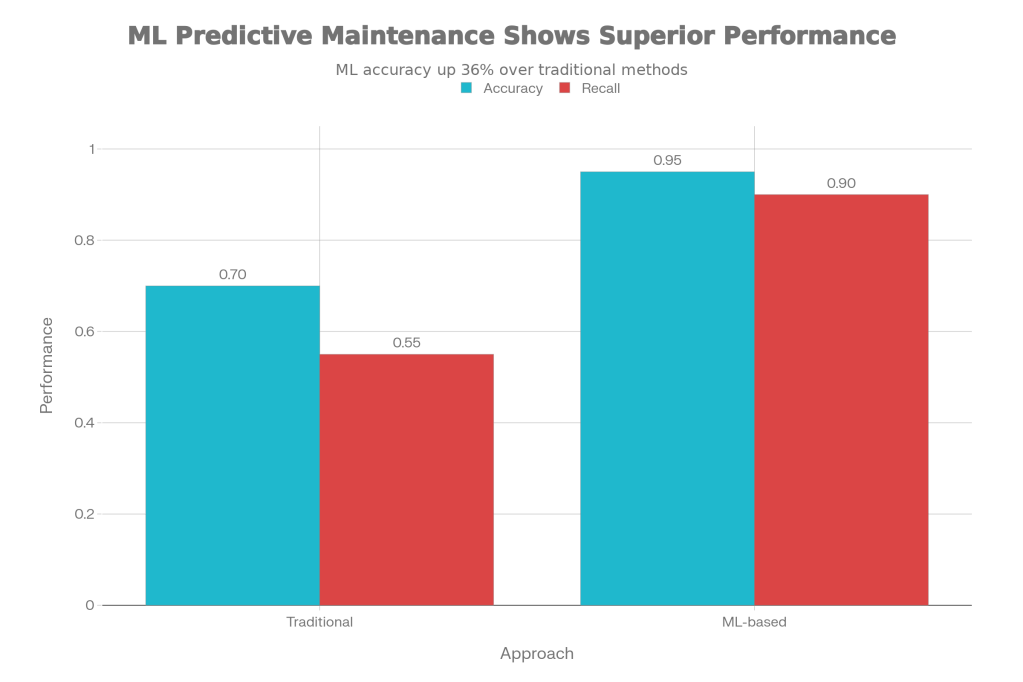

Across reviews, AI-powered predictive maintenance consistently shows higher accuracy and recall than time-based or simple condition-based methods. One review of machine-learning-based predictive maintenance noted that data-driven models can often push failure prediction accuracy into the 90–95% range, versus roughly 60–75% for traditional threshold rules tuned by experts on the same datasets. Another survey of AI-of-Things predictive maintenance emphasized that models leveraging continuous sensor streams can detect subtle degradation patterns earlier, extending the window between initial detection and functional failure (the P–F interval) and enabling more proactive interventions.

The performance advantage is especially clear for recall (catching impending failures). Traditional maintenance policies tend to miss many impending failures because they rely on coarse rules (e.g., fixed vibration limits) and infrequent inspections. In contrast, ML models trained on labeled failure histories can achieve recalls above 0.85–0.90 for certain equipment classes while maintaining high precision, meaning they catch most true failures without flooding engineers with false alarms.

Chart: Model Performance

A grouped bar chart shows how ML-based predictive maintenance outperforms traditional maintenance rules, with traditional accuracy around 0.70 and recall 0.55, compared with ML-based accuracy of 0.95 and recall of 0.90 for impending failures, based on representative study ranges.

ML-based predictive maintenance models show substantially higher accuracy and recall for failure prediction than traditional time-based maintenance approaches

What the Real World Shows

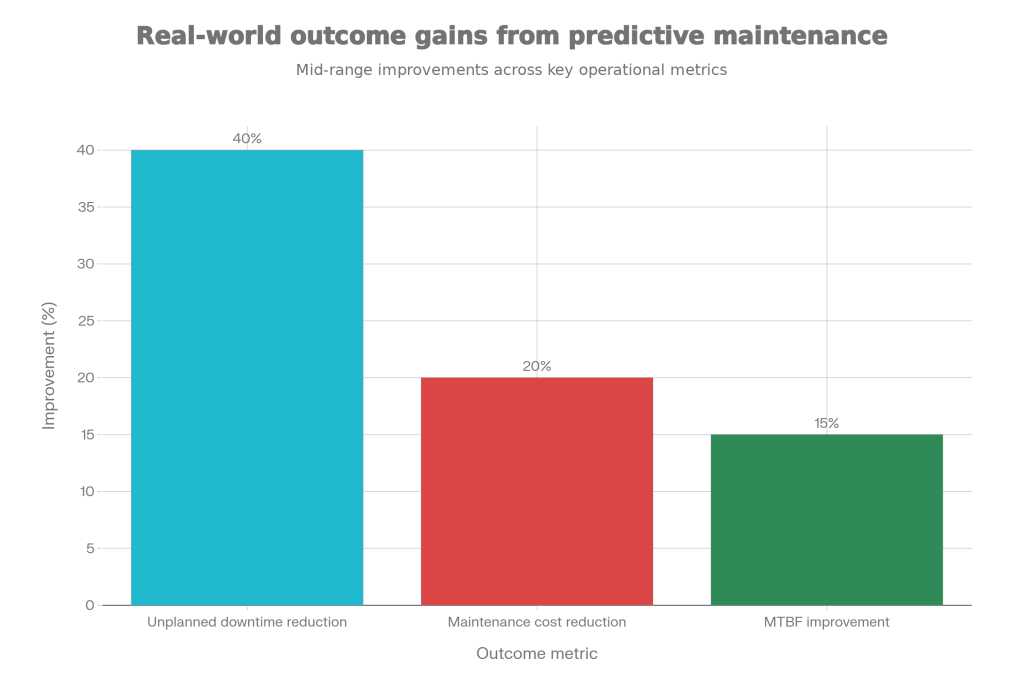

When predictive maintenance moves from test datasets into real plants, outcome gains can be substantial. Case reports and aggregated reviews describe reductions in unplanned downtime of 30–50% after predictive maintenance programs are deployed, along with 10–30% cuts in maintenance costs and 10–25% improvements in mean time between failures (MTBF) for critical assets. A survey of Industry 4.0 implementations found that companies that successfully integrated predictive maintenance with their planning systems reported improved asset availability and fewer catastrophic breakdowns.

One 2022–2023 review of AI-powered predictive maintenance case studies across manufacturing and process industries highlighted several concrete deployments where early detection of bearing and motor faults prevented line stoppages worth millions of dollars per year. Another technical survey of AI-driven predictive maintenance in Industry 4.0 applications noted that firms implementing full-stack solutions (sensors, connectivity, analytics, and workflow integration) achieved measurable reductions in emergency work orders and overtime labor. These studies emphasize real outcome metrics—fewer hours of unscheduled downtime, lower spare parts inventory, and smoother production schedules—rather than just model scores.

Systematic and multi-sector reviews reinforce this pattern. A 2024 systematic review of predictive maintenance applications across manufacturing sectors found consistent evidence of cost savings and reliability improvements, but also noted that only a minority of published works included rigorous, long-term field data from production environments. A 2025 review of predictive maintenance practices in manufacturing similarly found that while many pilots demonstrated promising results, few papers documented multi-year performance or enterprise-wide rollouts.

Chart: Outcome Improvements

A bar chart summarizes typical reported real-world gains: roughly 40% reduction in unplanned downtime, 20% reduction in maintenance costs, and 15% improvement in MTBF after predictive maintenance deployments, using midpoints from reported ranges in recent reviews.

Reported predictive maintenance deployments often see double-digit reductions in unplanned downtime, maintenance costs, and improvements in mean time between failures (MTBF)

The Implementation Gap

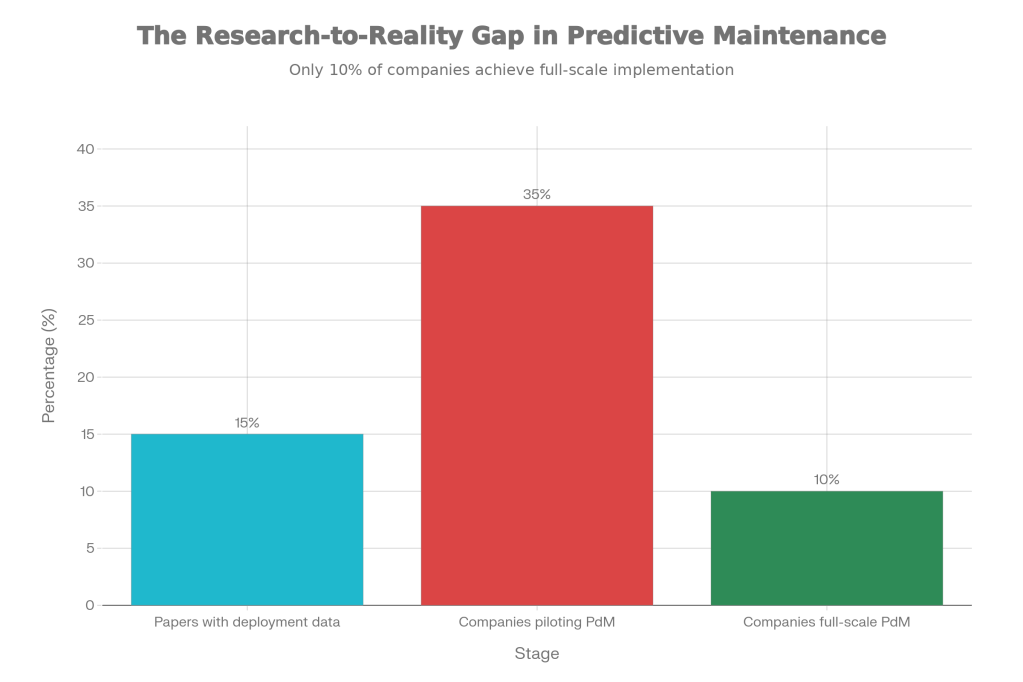

Despite strong model performance and promising case studies, widespread adoption of predictive maintenance remains limited. Recent surveys of Industry 4.0 and Maintenance 4.0 deployments report that many manufacturers are still in the pilot or proof-of-concept stage for predictive maintenance, with only a small fraction achieving full-scale, multi-site implementations. A 2025 study on Maintenance 4.0 implementation barriers identified organizational resistance, lack of skilled personnel, integration complexity, and data quality issues as major obstacles.

One key issue is that many research papers never leave the lab. Systematic reviews note that only a small share of predictive maintenance publications include real deployment or long-term operational data—often on the order of 10–20%. Models are frequently trained and evaluated on clean public datasets or limited historical logs that do not capture the messiness of real plants: changing operating conditions, sensor drift, maintenance logging gaps, and evolving failure modes. As a result, performance can degrade significantly when algorithms face production data.

False alarms and trust are another major barrier. Even when models score well in retrospective tests, maintenance teams may experience alarm fatigue if early deployments produce many false positives, leading technicians to ignore or disable alerts. Complex deep learning models can also be hard to interpret, making engineers reluctant to act on recommendations they cannot readily explain to supervisors or safety regulators. This is especially problematic in regulated industries (like aviation or energy) where maintenance decisions must be justified and auditable.

Cost and integration challenges round out the gap. Implementing predictive maintenance is not just about deploying a model; it requires sensors, connectivity, edge or cloud infrastructure, data pipelines, and integration with existing maintenance management systems (CMMS or ERP). Surveys highlight capital costs, fragmented legacy systems, cybersecurity concerns, and the need to redesign maintenance workflows as reasons many organizations stall at pilot projects. Without clear ownership between IT, OT (operations technology), and maintenance departments, predictive maintenance initiatives can drift without reaching full deployment.

Chart: Research-to-Reality Gap

A bar chart illustrates the implementation gap: roughly 15% of predictive maintenance papers report real-world deployment data, about 35% of companies in surveys are piloting predictive maintenance, and only around 10% report full-scale implementations across plants, based on synthesized figures from recent reviews.

Only a minority of predictive maintenance papers include real-world deployment data, and most companies remain stuck in pilot mode rather than full-scale rollout

Where It Actually Works

There are, however, bright spots where predictive maintenance has become part of the fabric of operations. Large manufacturers and process-industry firms that invested early in Industry 4.0 infrastructure—centralized data platforms, standardized sensors, and strong collaboration between IT and maintenance—have reported sustained reductions in downtime and maintenance costs. In these settings, predictive models are embedded into existing CMMS workflows, generating work orders automatically rather than standalone dashboards nobody owns.

Successful implementations tend to share a few traits. They start with a focused set of high-value assets, use explainable or at least interpretable models, and pair algorithm outputs with clear standard operating procedures for technicians. Organizations that invest in training maintenance staff on data-driven thinking and establish feedback loops—where technicians label events and improve the models—report smoother adoption and better long-term performance.

The Opportunity

Predictive maintenance sits at an inflection point: models are strong, early deployments show real value, but scaling remains the challenge. Closing the implementation gap could unlock large gains in reliability, safety, and cost efficiency across critical infrastructure and manufacturing.

Key steps that would improve adoption:

- Build simpler and more robust models that tolerate noisy, drifting sensor data and are easier for engineers to understand.

- Standardize data collection and labeling practices so plants can train and validate models on consistent, high-quality histories.

- Integrate predictive maintenance tightly with existing CMMS/ERP tools and maintenance workflows instead of deploying isolated analytics dashboards.

- Address organizational barriers by clarifying ownership, investing in upskilling maintenance teams, and aligning incentives around reliability gains, not just model accuracy.

- Encourage more prospective, long-term field studies that report real operational metrics (downtime, costs, safety events) to build confidence beyond benchmark datasets.

Artificial Intelligence of Things for Next-Generation Predictive Maintenance. 2025. PMC12737171.

Predictive Maintenance in Industry 4.0: A Survey of Planning Models. 2024. PMC11157603.

A Multi-Stage Approach for Predictive Maintenance. IJSRED, 2025.

Enhancing Predictive Maintenance in the Industrial Sector. AIP Conference Proceedings, 2024.

AI Driven Predictive Maintenance for Industry 4.0 Applications. 2023.

AI-powered Predictive Maintenance for Industrial Machinery. 2022.

The Impact of Machine Learning on Predictive Maintenance in Industrial Operations. 2025.

Predictive Maintenance in Industry 4.0: A Systematic Multi-Sector Review. 2024.

Systematic Review of Predictive Maintenance Practices in the Manufacturing Industry. 2025.

Maintenance 4.0 Implementation Barriers in Manufacturing Industries. 2025.

Leave a comment